By Matthew O’Keefe

The Millig Difference:

Addressing School HVAC Performance Issues

Millig Design Build recently replaced a 50-ton rooftop unit (RTU) to improve HVAC performance for our client’s Middle School building. The new unit was landed on the roof, powered up, and was following the existing control sequence properly - but comfort complaints still happened on a near daily basis. What are the reasons behind this?

It's important to understand and highlight that what Millig did next is not standard practice. Typically, a commissioning agent, general contractor, or other party would not delve into these issues as part of their project scope . However, The Millig Difference focuses on proactively identifying and correcting issues, even when they fall outside our contractual obligations - saving our clients time, money, and potential headaches.

Millig’s First Step: Identifying the Core Issue

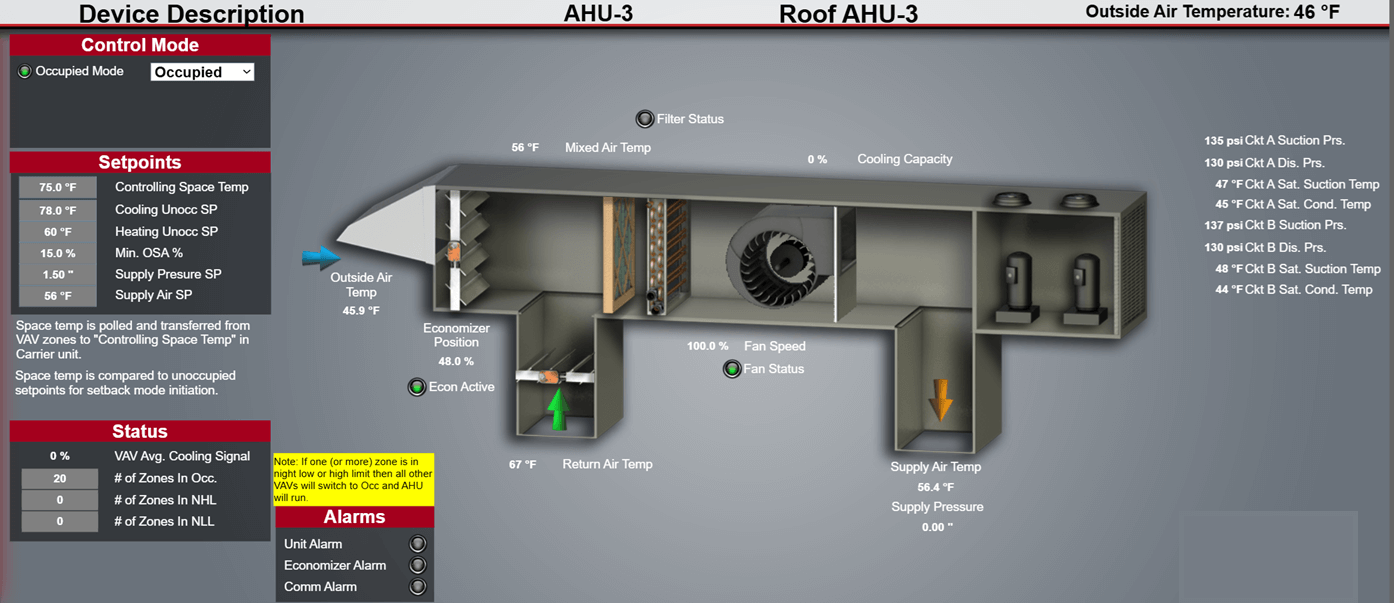

The new RTU unit is integrated into a Variable Air Volume (VAV) system that serves multiple zones. Through a thorough review of the Building Automation System (BAS) trends, Millig’s commissioning team confirmed the new RTU was functioning as designed, with the exception of a not-installed-yet supply static pressure sensor.

Picture 1: BAS graphic for the newly installed RTU

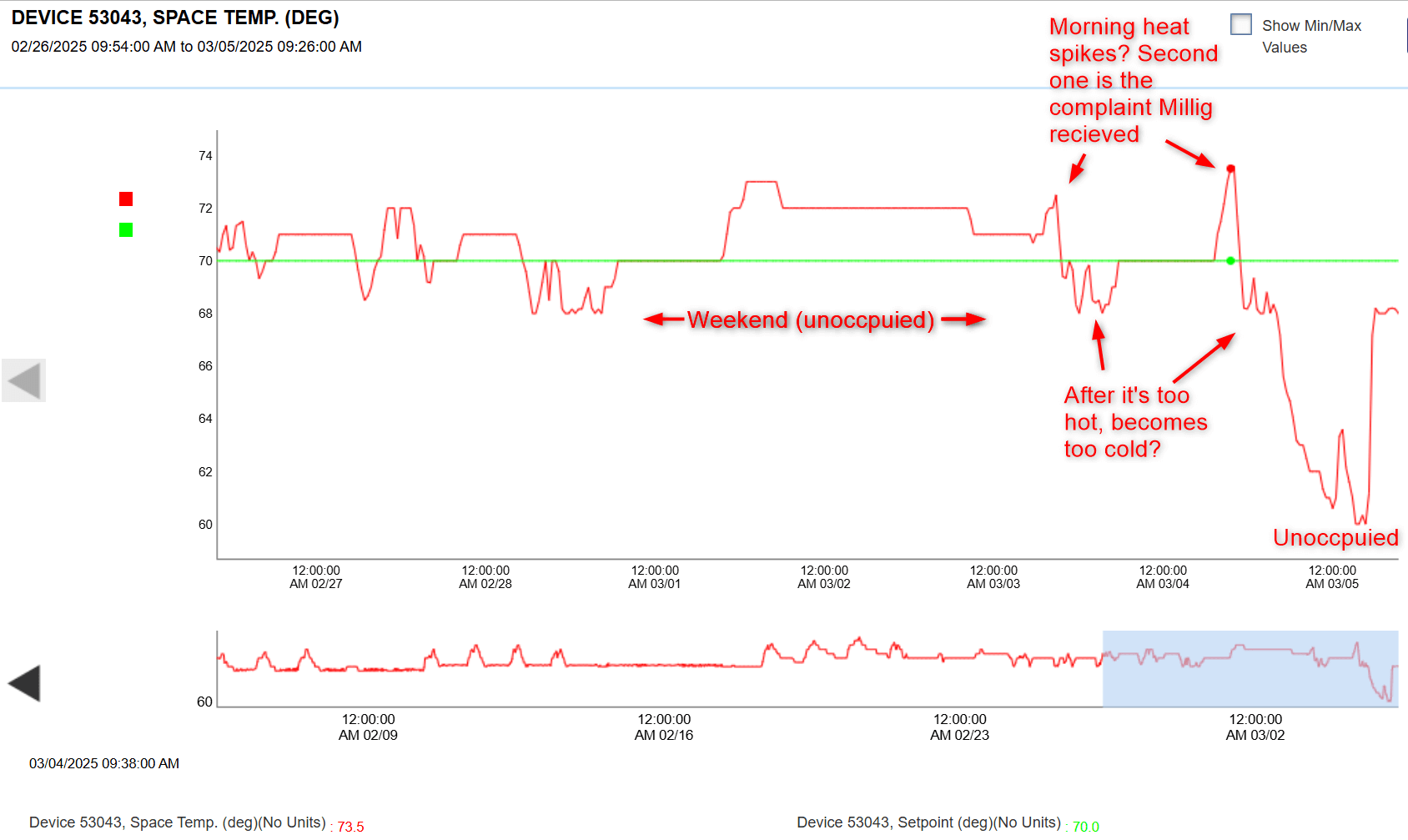

However, Millig also identified that the spaces were struggling to maintain their individual thermostat setpoints. Despite the RTU supplying adequately cold air (55-56°F), the spaces experienced temperature fluctuations, being excessively warm in the morning and then too cold in the afternoon.

Picture 2: BAS Trends for problematic VAV zone

The root of the problem was traced back to the VAV box, which was failing to properly control airflow into the zone. Given that VAVs control both ventilation and temperature, any malfunction in airflow control inevitably results in inconsistent heating and cooling cycles. This specific airflow control issue stemmed from the VAV's airflow damper being perpetually forced open, thus preventing proper modulation.

Consequently, the system continuously delivered a high volume of cold air. During the morning warmup phase, the VAV box initiates reheat to assist the zone in reaching the desired temperature. However, the required reheat was excessive, needing to counteract the constant influx of cold air, far exceeding the space's typical heating demands. This likely explains the "too hot" complaints. As the day progressed, solar gain and occupancy increased the building's temperature, reducing or eliminating the need for reheat and potentially requiring cooling. Nevertheless, due to the damper being fixed in the open position, the room continued to receive maximum airflow regardless of the actual needs. This resulted in the overcooling complaints. In essence, when a VAV is unable to effectively control airflow, its ability to regulate zone temperature is compromised.

Initial Key Findings

The RTU trends indicate that it follows the control temperature setpoint, meaning it does what it should be doing and the issue probably lies within the VAVs

The trends for a single VAV in the system shows temperature swings, but not any damper response, implying “non-functional” controls which could be due to a number of reasons.

Millig’s Immediate Action Plan

To quickly address these issues and prevent ongoing occupant complaints, Millig recommended the following corrective actions:

Restore airflow control and verify full damper movement (0%-100%) by physically inspecting it

Using the BAS, ensure that each VAV box is properly controlling airflow

Expand the verification process to all VAVs in the middle school and other facilities within the District

Long-Term Best Practices Recommended by Millig

Additionally, Millig advised the client to implement the following long-term best practices:

Regularly review system graphics to quickly detect problematic zones

Document any manual overrides with timestamps and explanations for future troubleshooting

Ensure clear labeling of system trends for better data interpretation

Confirm that all airflow setpoints align with design specifications and/or ASHRAE ventilation standards.

Consider investing in client-owned airflow measurement equipment or hiring a Test and Balance (TAB) contractor to verify airflow accuracy throughout the district buildings.

Monitor existing sequences to verify they work properly, i.e. monitoring based commissioning

By applying these recommendations, the school will be empowered to address these airflow issues as they happen again in the future, reinforcing the importance of knowledge and proactive maintenance.

About Matthew O’Keefe

Matthew O'Keefe is a commissioning agent with Millig Design Build. His duties include verification of both proper installation and performance for various building systems to maximize efficiency and comfort. Matt has 13 years of engineering experience, 8 of which are in the field of building science and efficiency. With a deep background of mechanical systems, controls, troubleshooting, and effective communication, Matt takes pride in improving every site he works on and supporting everyone he works with.

OUR SOLUTIONS

Heating, ventilation, and air conditioning

Smart meters and building controls

On-site solar and other renewable energy systems

LED lighting retrofits

Building envelope improvements

Water systems

CHP-Cogeneration

And more

CONTACT US